In almost every modern factory, there is a quiet helper doing heavy work without sparks, flames, or loud engines. That helper is the pneumatic cylinder. While most people notice motors and electronics first, pneumatic cylinders deserve just as much attention. They are responsible for moving parts, lifting loads, guiding products, and supporting automation in thousands of industries worldwide.

Understanding the Pneumatic Cylinder in Simple Terms

A pneumatic cylinder is a device that uses compressed air to create straight-line motion. Instead of rotating like a motor, it pushes or pulls in one direction and then returns back again. This movement is known as linear motion.

Inside the cylinder is a sealed chamber containing a piston. When air is forced inside, pressure builds and pushes the piston forward. The piston is connected to a metal rod, which transfers that movement to the outside world. When air is released or redirected, the piston moves back to its original position. This open-and-close action may seem basic, but it is extremely powerful when repeated thousands of times.

The brilliance of the pneumatic cylinder lies in its simplicity. Use air, control the airflow, and the piston does the work. No fuel, no burning, no complicated systems.

How Pneumatic Cylinders Actually Work on the Factory Floor

Compressed air is usually produced by an air compressor and stored in a tank. From there, it travels through pipes and hoses into the cylinder. Valves control when air enters, when it exits, and which side of the piston receives pressure.

When air fills one side of the piston, it pushes the rod outward. When the air shifts or escapes, pressure changes and pulls the rod inward. Valves, timers, and sensors can control this process with great accuracy, allowing machines to repeat precise movements all day long.

The speed of movement depends on airflow. The force depends on pressure and piston size. A wider piston delivers more force, just as pushing with a larger hand surface produces more strength.

Some cylinders use air in one direction and a spring to return. Others use air for both extension and retraction. Both styles serve different industrial needs.

Functions of Pneumatic Cylinders Across Industries

Pneumatic cylinders may power machines, but they also manage delicate tasks.

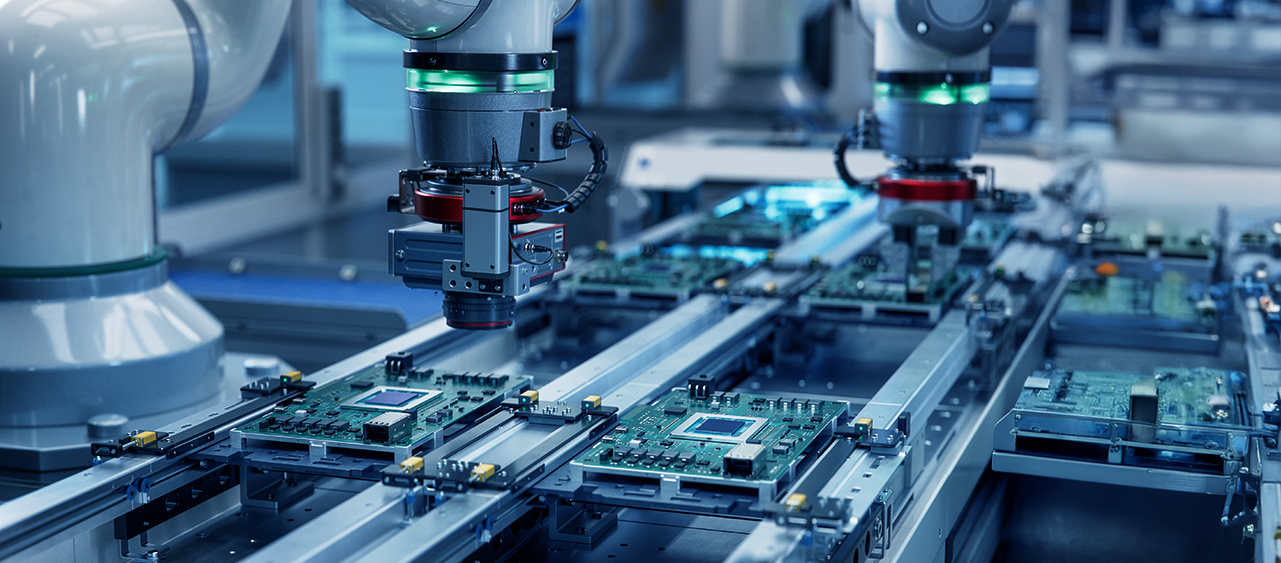

They push boxes down conveyor belts in warehouses. They lift components into place during assembly. They hold pieces steady while cutting or welding takes place. They operate automatic doors, sorting tools, clamping systems, and robotic equipment.

In the food and medical industries, pneumatic cylinders are especially valuable because they run cleanly. There is no oil leakage and no contamination risk, making them ideal for sensitive environments.

In vehicle manufacturing, they assist robotic arms and positioning equipment. In packaging, they control sealing, labeling, and sorting actions. In woodworking and metal shops, they clamp materials securely for shaping or drilling.

Few machines operate today without at least one pneumatic cylinder hidden inside.

Why Industries Continue to Choose Pneumatics

One major reason pneumatic cylinders are so popular is safety. Air does not explode or burn. That makes pneumatic systems dependable in environments where sparks or heat would be dangerous.

Another major benefit is cost. Air is free, and basic pneumatic systems are less expensive to maintain than powered alternatives.

Pneumatic cylinders are also lightweight compared to hydraulic systems, allowing smaller machines with strong performance.

Maintenance is straightforward. When a seal wears out or air leaks form, parts can be replaced quickly. Systems rarely require long shutdowns.

Energy efficiency is another reason industries rely on pneumatic power. Well-designed systems use just enough air to perform each movement, conserving electricity and reducing costs.

Design Quality Makes the Real Difference

Not all pneumatic cylinders perform equally. Precision engineering matters. Poor sealing, rough surfaces, and weak materials lead to air loss and inefficiency.

That is why industries choose experienced pneumatic cylinder manufacturer and trustworthy suppliers who understand load requirements, pressure limits, and operating conditions.

Quality design ensures consistent motion, minimal air leakage, long service life, and stable performance over millions of cycles.

Final Words

A pneumatic cylinder may seem simple, but it is one of the most powerful tools behind modern automation. It transforms invisible air into visible action and keeps industrial operations moving smoothly. With intelligent design and correct application, pneumatic cylinders remain one of the safest, cleanest, and most dependable motion systems in industry today.